Gear Design

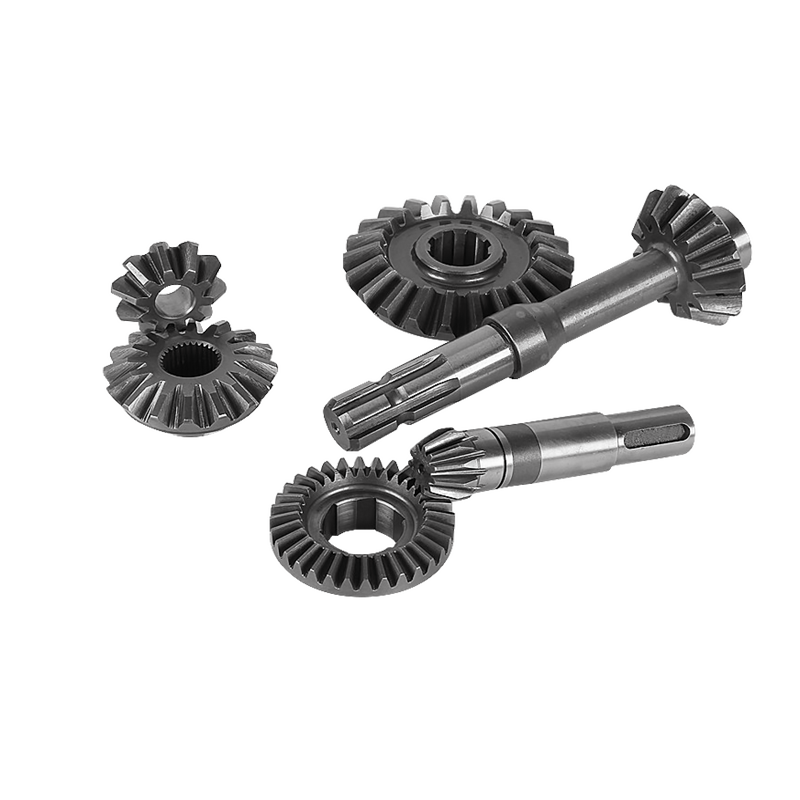

High precision lawn mower gears designs often utilize involute tooth profiles, which provide smoother transmission and higher efficiency. Involute gears have a larger contact surface, which reduces wear and tear, thus extending the life of the gears. In addition, many modern mowers utilize a dual gear system, which provides better power transmission and higher cutting efficiency under varying operating conditions.

Material choices

When it comes to materials, durable garden mower gears are often made from high-strength alloy steels or specially treated materials that offer excellent wear and corrosion resistance. For example, some lawn mower gears feature an all-metal gear design, which dramatically increases their durability and efficiency. In addition, the use of high-quality materials reduces the frequency of maintenance and lowers long-term costs.

Manufacturing Process

The manufacturing process for high-precision gears is also critical. Modern mowers often utilize CNC machining technology, which ensures that the gears are dimensionally accurate and consistent in shape, thus improving overall performance and reliability. With precision tools and machining equipment, manufacturers are able to produce gears that meet tight tolerances, ensuring their stable operation under high loads.

Conclusion

To summarize, the features of gears for high-precision and durable horticultural lawn mowers include advanced design concepts, high-quality material selection, and precision manufacturing processes. These features not only enhance the performance of the mower, but also ensure its reliability and durability in various environments, providing users with a better experience.